As noted in our recent blog, the demand for higher volume and more efficient carbon composite material manufacturing is pushing technological advancements in laser-based automated fiber placement (AFP) techniques forward. These new methods introduce key advantages which can save manufacturers time and money.

When developing a system, integrators need to balance several aspects of its components. The right choice of diode laser as the key heating component in such a system can help in making a flexible tool. Several factors contribute to choosing a diode laser that provides sufficient power and heat uniformity in a compact size, without the risk of overheating.

Consider these three variables when evaluating AFP diode laser sources:

- Power: The power of a diode laser module can be customized from just a few watts to 10s, even 100s of kilowatts. For an AFP application, typically 1 kilowatt or less per tow is sufficient. The exact power depends mostly on the material and the processing speed. High speeds also require the ability to control the power on a fast (millisecond or kHz) time scale.

- Size and weight: A compact diode laser system allows for a more compact AFP head. While a more compact AFP head is nimbler and can maneuver more intricate structures, such a head also has less mass and can therefore be moved faster with the same force. Applying the same force allows the system to be manipulated with higher accelerations. Finally, a smaller component can be more easily integrated into the system as it offers more flexibility.

- Beam homogeneity: The amount of heat, and therefore light, needs to be uniform across a designated target area. With beam conditioning optics, advanced diode lasers can be designed to provide up to 99% uniformity.

As the industry embraces AFP for the bonding of modern composite materials, diode laser heating can increase overall throughput, efficiency and ROI. Modular diode design can further improve the versatility and precision of these industrial systems.

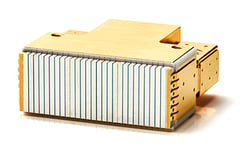

Leonardo is meeting this demand with our compact T6 fluid-cooled diode array that can achieve 60% or more power conversion efficiency. This scalable model provides uniform high power beams, ideal for use in AFP systems at a fraction of the size of other diode laser systems. The T6 can be used as a customizable building block for system integrators. Custom beam shaping with extremely small optics and the ability to stack each module into a custom shape, while maintaining full control of each element, opens the door to perfect-fit AFP systems for any manufacturing facility. This module also offers rugged construction for use in robotic arms that undergo very high accelerations.

Learn more about AFP technology and diode lasers in our white paper.

Ready to learn more about the T6 for your project? Contact us today.