Today, the US Department of Defense’s directed energy program has achieved a significant milestone—fielding a directed energy laser into a ship’s weapons systems, authorized for use upon command. There is much progress to be made, but leaders in the field of directed energy are making great strides to overcome long-standing concerns around usability, scalability, and power requirements for viability.

As participants and presenters at the recent DEPS Summit (www.deps.org), Leonardo Electronics US leadership and engineering teams shared a brief update on the state of technology in three different fields of directed energy. Because of the nature of this summit, much of the technical information and discussion cannot be disclosed in a public setting. For additional details or to book a private briefing, contact us. We can, however, share the latest advances and challenges of the three major laser technologies within directed energy:

- Fiber lasers

- Solid state lasers

- Alkali lasers

All three laser technologies offer application advantages and can be advanced by power and efficiency improvements to the diode pump source. Leonardo is a market leader in diode pump sources for fiber lasers, solid state lasers and alkali lasers, and continues to innovate to improve SWaP to help meet DoD performance requirements.

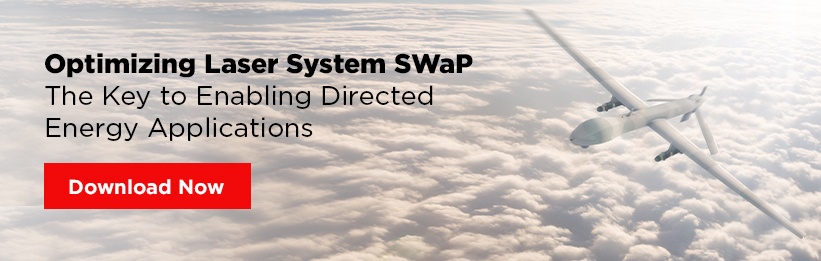

Fiber Lasers for Directed Energy

Of the laser technologies, fiber lasers are considerably the furthest along. They’ve been fired, tested, and used by soldiers in real world situations—all of which are considered critical parameters. Lower powered fiber lasers, in the 5-10kW range, have the highest TRL, or Technology Readiness Level. Higher power applications are still in development with a lower TRL. This is largely because most DE fiber lasers originate from commercial industrial laser material processing systems and are being repurposed for directed energy usage. While this commercial base provides advantages in readiness, as well as good heat dissipation, efficiency, manufacturability, and rugged, compact packaging, it also presents some performance challenges unique to directed energy applications:

- Brightness

- Back reflections

- Conversion efficiency of electrical to optical energy

- Industry expectations for narrow absorption at 976nm peak

Figure 1: Schematic of a directed energy fiber laser

Improvements in efficiency and power in the pump source improve overall performance of the fiber laser. Leonardo Electronics US Inc. has developed the F8 fiber coupled laser diode, a 500W fiber coupled pump, as an example of their capabilities for fiber lasers. Higher power and lower SWaP versions are being developed as well as pump sources that operate using 2-phase cooling and at higher operating temperature points. This allows for not just a scaling up of power, but reduction in the overall size and weight of the pump diode and cooling system.

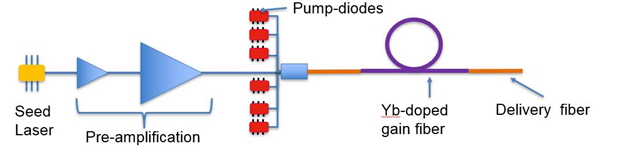

Solid State Lasers

Leonardo is the primary supplier of diode pump sources for solid state lasers. These lasers offer high efficiency, a stable beam, and rugged packaging. They show tremendous promise for high energy applications requiring powers over 100kW.

Figure 2: Schematic of a directed energy solid state laser

To address both thermal management and scalability, Leonardo introduced the T6 fluid-cooled laser diode array, which offers a modular, stackable approach and rear thermal management to optimize efficiency. [Learn more in this SPIE technical paper: T6 laser diode array advancements for high-power applications] As outlined in the recent published SPIE paper, the T6 has been demonstrated in a solid-state laser to deliver >50kW from a 50-bar array and power scalability up to 1MW.

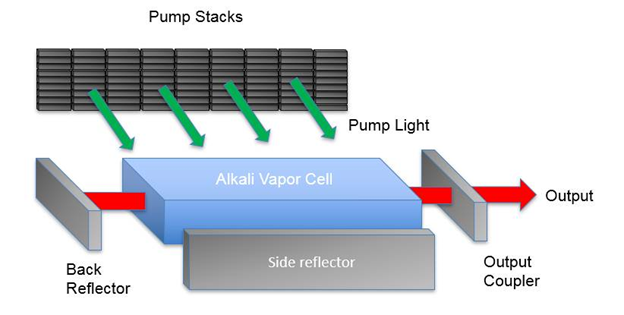

Alkali Lasers

The third technology for directed energy, the diode pumped alkali laser, is very similar to solid state lasers, except that the gain medium is a vapor instead of a crystal. Because the gain medium is a gas, it’s better at heat dissipation. The alkali laser also offers good beam quality—with no need for separate lasers that combine into one beam.

Figure 3: Schematic of a directed energy alkali laser

Alkali lasers have the potential to scale to powers over 1MW while maintaining excellent beam quality. The industry currently views this as the entry level power identified for several applications such as ballistic missile and hypersonic weapon defense.

The US DoD believes directed energy is now advanced enough that it must come out of the lab and into industry. Fielded directed energy laser weapon demonstrations are continuing to take place to gain feedback from the user community. Laser manufacturers, such as Leonardo, continue to develop components that will enable higher power lasers to be deployed on even smaller platforms. Speed of light target engagement has never been closer to reality.

Directed Energy Trends & Current Questions

As the technology advances to meet emerging directed energy industry requirements, we hear these questions and concerns:

- Higher power—more, more, more

- How can we simplify thermal management? Conductively cooled or fluid cooled?

- Higher efficiencies—more output, less weight

Leonardo invests heavily in R&D to reduce weight and size and increase power at the diode level. Our development teams look for opportunities to drop diode system’s weight and size. In addition, we continue partnering with government labs and US DoD primes to help bring directed energy lasers to technology and manufacturing readiness.

Contact us for a private briefing or to discuss your requirements.